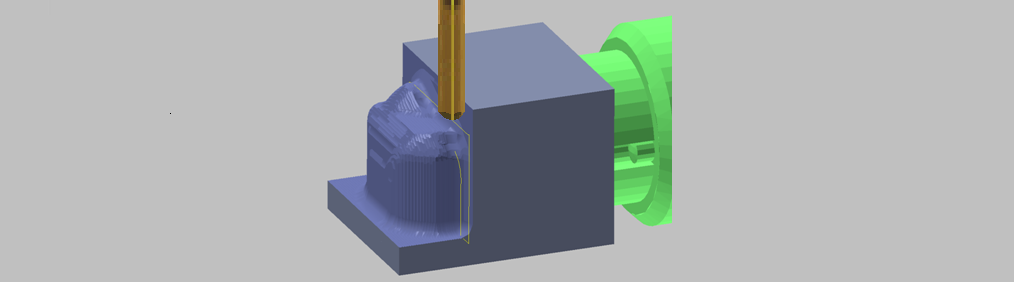

Axis-parallel roughing of glass ceramics and lithium disilicate using diamond-coated tools. Particularly well suited for use with 3+1 machines that do not support other roughing strategies for kinematic reasons.

The cycle can be configured in such a way that the toolpath ascends consistently.

|

Cycles

|

3D axis parallel peeling

Drilling inside copings (to prepare for a

5X peeling job).

5X peeling

3D U peeling

|

Machining direction

|

X/Y, positive/negative

Specify the machining direction in X/Y, positive or negative direction.

|

From inside to outside

|

|

From outside to inside

|

|

Type of cut

|

Defines the manner of the tool movement.

|

Ascending

|

The tool only ascends during machining. Recommended machining mode for glass ceramics and lithium disilicate.

A full cut is not permitted. For the internal machining of copings, for example, the area must be pre-drilled to allow the tool to plunge.

|

Ascending + Descending

|

The tool moves in an ascending and descending direction during machining.

A full cut is permissible.

|

There is the risk of tool breakage during full-cut machining with grinding tools and with tools that are not designed for plunging into the material on the front side.

|

Step down

|

Infeed per cut. The maximum infeed depends on the tool and the blank.

As a Z-limit boundary, a plane is always created at the lowest point of the equator.

Machining is always performed orthogonally to the blank – irrespective of the setting in the template.

Provided the length of cut of the selected tool is sufficient, the step down can correspond to the value of the blank depth for the purposes of optimal calculation and milling times.

|