Machining after roughing on any side until the desired surface quality is obtained for the part and no rest machining tasks remain.

|

Cycles

|

3D Z-Level finishing

3D complete finishing

3D equidistant finishing, suitable for front-side finishing of Blue Blocks

5X Z-level finishing

Radial 5X equidistant finishing with the option of radially retracting and omitting/skipping (clipping) the connector, e.g., for grinding jobs on the connector side of Blue Blocks.

|

Side

|

Front/back/left/right/top/bottom

Enter the side to be machined; corresponds to the viewing direction configured [Front view].

|

Machining depth

|

Parameters for the machining depth applied to the blank.

|

Max. of bounding box

|

Machining area based on “back” view of the blank (bounding box).

|

Min. of bounding box

|

Machining area based on “from back to front” view of the blank (bounding box).

|

Center of bounding box

|

Machining area based on “from back to center” view of the blank (bounding box).

|

Bottom of blank

|

|

Top of blank

|

|

Offset depth

|

mm

Additional value for the machining depth. A larger value results in deeper machining.

|

Use/transform fixture boundary

|

|

Yes

|

When machining a side of the blank,

use milling boundaries for holders.

|

No

|

When machining the front side (from the perspective of the fixture).

|

Tilt strategy

|

|

Automatic

|

The lead angle is calculated automatically.

|

Radial Z

|

Enter lead angle is entered manually.

|

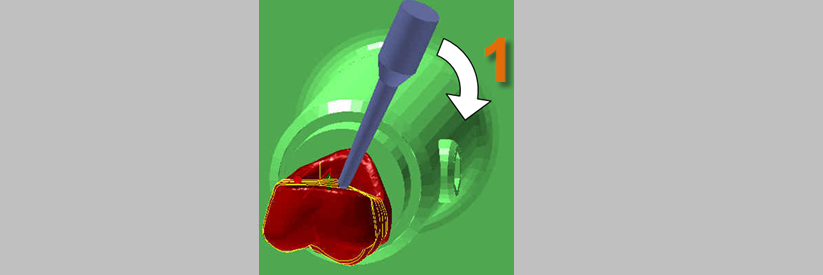

1) Lead angle

|

Lead angle

|

Lead angle setting.

|

Desired tilt angle / max. angle of inclination

|

Tilt angle with respect to the Z axis.

|

1) Tilt angle

|

Max. avoidance angle A/B

|

Maximum angle for avoiding collisions with regard to the A/B-axis.

|

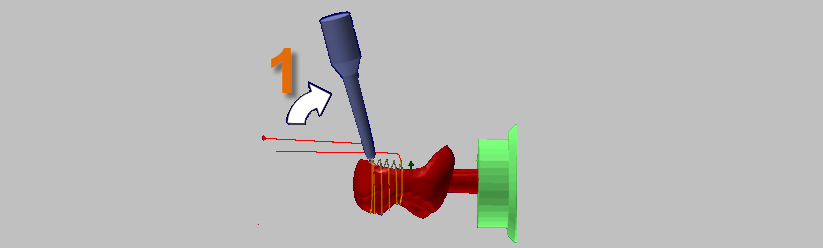

Center at connector position

|

Use this to obtain clean cutting paths around the connector.

|

Yes

|

The center of the connector is the pivot point for the toolpaths around the connector.

|

No

|

The center of the part is the pivot point for the toolpaths around the connector.

|

Invert infeed direction

|

Reverse the machining direction.

|

Close caps

|

|

Yes

|

You must select “Yes” if the “Special function coping-specific alignment” option has been configured for the part.

You also need to select “Yes” for the following finishing cycles of the cavity.

|

|