Adjusting the Position and Size of Special

Color Plates

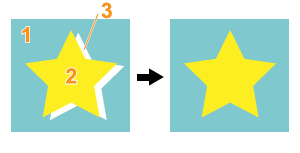

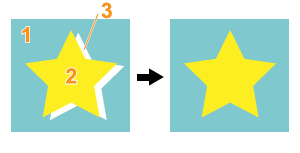

The special color plate correction function corrects for misalignment

in special color printing by expanding/reducing the special color printing

image and by fine-tuning the position of this image. You can easily check

the correction values by printing a test pattern.

| Position

correction |

|

|

1

Media

2 Process color

3 Special color |

| Size correction |

|

|

|

Depending on the printer, this function may not be

displayed.

Correcting the position

Correcting the size

Correcting the position

Adjust the printing position of the special color ink.

- Double-click

or

or  .

.

The [Queue A (B) Properties] window appears.

- Click

.

.

Under [Quality Settings], use [Mode]

to select the special color ink mode to use.

- Click

.

.

- Use the [Special Color] list box under [Special Color

Plate Correction] to select the special color ink to correct.

- Click [Test Print].

The [Test Print] dialog box appears.

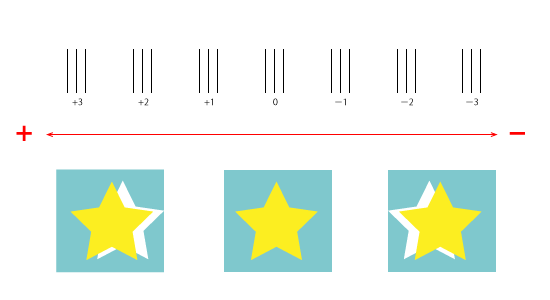

- Select [Pattern Settings].

Simple

Select this to make rough adjustments to position misalignments.

Detailed

Select this to make detailed adjustments to position misalignments.

- Click [OK].

A test pattern is printed.

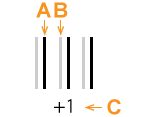

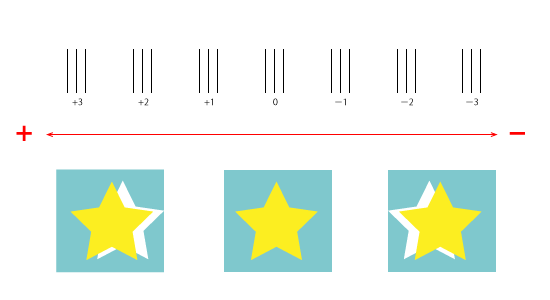

| Correction position

and printing position in the horizontal direction |

|

| Correction

position and printing position in the vertical direction |

|

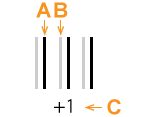

- Enter the [Horizontal] and [Vertical] correction

values.

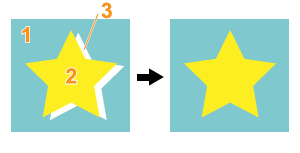

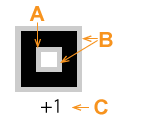

Select the values on the printed test pattern that make the misalignment

between A (the black line) and B

(the special color line) the smallest. Enter the C

values (which represent the [Horizontal] and [Vertical]

correction values) written on the test pattern.

|

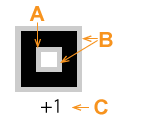

A

Black line (reference line)

B Special color line

C Correction value |

Note

The test pattern correction values differ for each piece of data.

Set the correction values for each piece of data.

- Click [OK].

If you have to adjust the size of the special color printing data,

proceed to Correcting the size.

Tip

• These settings can be customized per job using the [Job Settings]

window.

Correcting the size

Adjust the printing size of the special color ink.

Tip

If you will correct the size, we recommend that you first correct the

position.

- Double-click

or

or  .

.

The [Queue A (B) Properties] window appears.

- Click

.

.

- Use the [Special Color] list box under [Special

Color Plate Correction] to select the special color ink

to correct.

- Click [Test Print].

The [Test Print] dialog box appears.

- Select [Pattern Settings].

Simple

Select this to make rough corrections.

Detailed

Select this to make detailed corrections.

- Click [OK].

A test pattern is printed.

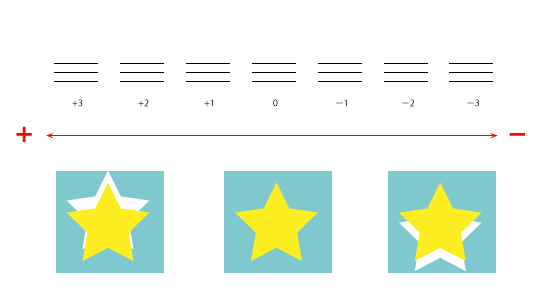

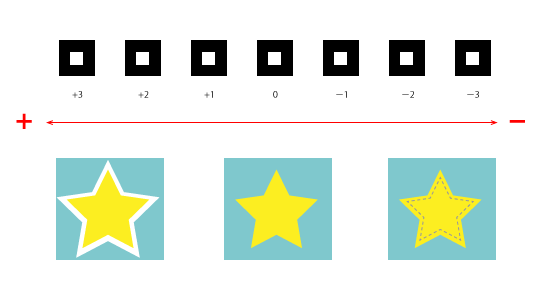

| Size

correction value and printing position |

|

- Enter the [Size] correction value.

Select the value on the printed test pattern that makes the

misalignment between A (the black line) and

B (the special color line) the smallest.

Enter the [Size Correction] value written on the test

pattern.

|

A

Black line (reference line)

B Special color line

C Correction value |

Note

The test pattern correction values differ for each piece of

data.

- Click [OK].

Tip

• These settings can be customized per job using the [Job

Settings] window.

or

or  .

. .

. .

.

or

or  .

. .

.