Configuring the Printer Control Settings

You can configure the control settings of your printer from VersaWorks

Dual. Although in general you don't need to change any of these settings,

some settings may need adjustment depending on the media type of task.

Optimal settings are automatically applied when you select the media.

Follow the procedure below to configure the printer control settings.

Print size correction

- Double-click

or

or  .

.

The [Queue A (B) Properties] window appears.

- Click

.

.

- Configure the following settings as necessary.

[Cut Sheet after Output]

Select this to cut the media after each job is printed.

[Use Custom Settings]

Check this option if you want to change the following items as.

[Page Space]

Select this to specify the amount to feed the media after printing.

[Overprint]

Select this to perform overprinting.

Performing overprinting uses a large amount of ink, so smudging

or uneven printing may occur. Perform test printing to check

whether the desired printing results are obtained.

In order to configure

[Feed Calibration Controls],

[Other

Controls] and

[Heater Controls], select how you want

to control these options from one of the following:

Use Default Media Settings

|

Uses the recommended settings for the media selected

in [Media Name] in [Quality Settings]. |

Use Custom Settings

|

Uses the settings configured in this window. |

Use Printer Settings

|

Uses the settings configured on your printer. |

The following options can be configured only when

[Use Custom

Settings] is selected.

[Feed Calibration Controls]

When using non-genuine media, you need to configure the feed calibration

on your printer or VersaWorks Dual. When configuring in VersaWorks

Dual, measure the feed calibration on your printer, and then enter

the measured value in [Feed Calibration].

For information on how to measure a feed calibration, refer to

the documentation of your printer.

[Other Controls]

[Vacuum Power]

Configure the intensity of the vacuum to hold the media flat

on the platen.

Increase the power when the media often gets curled or buckled.

When using soft media, decreasing the power may improve the

media feeding.

[Dry Time]

Configure time (in minutes) to wait before printing the next

page or perform cutting. For example, when you need the printed

surface to be completely dry when performing printing and

cutting, you can set the drying time.

[Head Height]

Configure the height of the print head for printing. In general,

this setting should not be changed.

[Heater Controls]

[Pre Heater], [Print Heater], [Dryer]

Select each device to configure the temperature settings of

the device.

Deselect to turn off the device when printing.

[UV Lamp Adjustment]

Turn this on when you want to change the UV lamp illumination

intensity. If you change [Media Name], [Print Quality],

[Resolution], or [Mode], you will have to set the

illumination intensity again.

Note

Changing the illumination intensity can have an effect on printing

quality (the ink may not cure, or banding and unevenness may occur).

Use caution when changing this setting.

Note

- Depending on the printer, some settings may not be available.

When using the printer that does not have the dryer temperature

control feature, you can turn on/off the dryer by selecting/deselecting

[Dryer].

- Click [OK].

Tip

- These settings can be customized per job using the [Job Settings]

window.

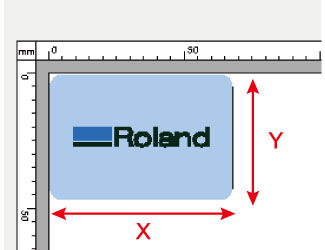

Configuring the print size correction

A shifted print result can be corrected by adjusting the horizontal

and vertical sizes of the print data. By entering the measured sizes (actual

print size) and expected sizes (size to be printed), the correction factors

can be automatically calculated and easily set. Otherwise, you can directly

enter the correction factors.

Depending on the printer, these settings may not appear.

Setting the correction factors based on measured values

Setting the same correction factors for added images

Note

- Cut lines will not be adjusted.

- Variable data printing and nested jobs will not be adjusted.

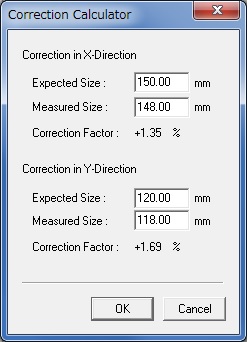

Setting the correction factors based on

measured values

By entering the expected and measured sizes, the correction factors

will be automatically calculated.

- In the job list, double-click the job.

The [Job Settings] window appears.

- Click

.

.

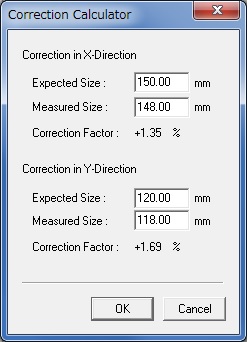

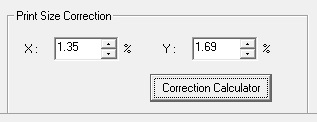

- Click [Correction Calculator].

The [Correction Calculator] window appears.

- In [Expected Size] and [Measured Size], enter the sizes in

the X and Y directions.

* The correction factors can be set within

a range of -5.00% to +5.00%.

[Expected Size]: Enter the size to be printed.

[Measured Size]: Enter the measured size of the print

result.

[Correction Factor]: Automatically calculated based

on the entered values.

- Click [OK].

- The previous window appears with the settings entered.

- Click [OK].

Tip

- The correction factors can be directly entered.

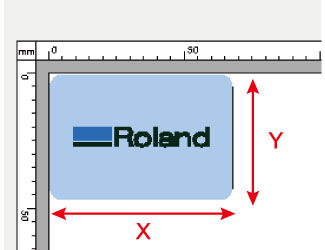

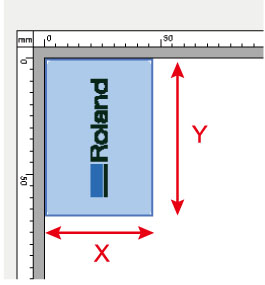

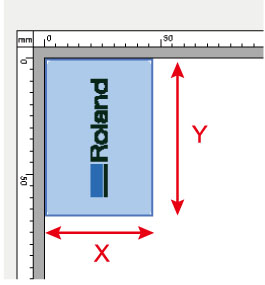

Correction directions

<

The X direction refers to the width of the preview image and the

Y direction refers to the height.

Even if the image has been rotated, the X direction will be the

width of the preview image and the Y direction will be the height.

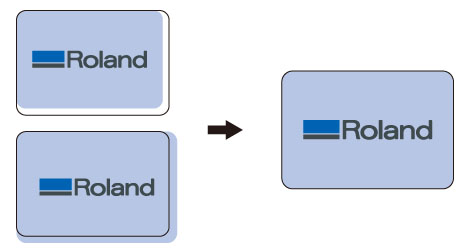

Setting the same correction factors for

added images

Specifying the settings from a job list will apply the corrections to

any images added to the job list.

or

or  .

. .

.