There are two locations in which you can install the cutting carriage tool.

Normally install it in the rear position. Install it in the front position when cutting perforated lines.

If you enable [BLADE DETECT] and send the cutting data, the tool's installation position will be checked before cutting starts.

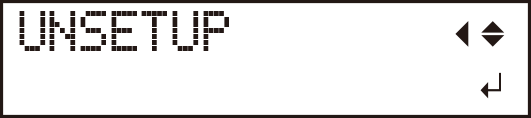

If the tool is installed in the incorrect position, operation will be paused and the following message will be displayed to prompt you to install the tool in the correct position.

<When the cutting tool is installed in the front position and normal cutting is being performed>

![]() * R = Rear

* R = Rear

<When the cutting tool is installed in the rear position and perforated cutting is being performed>

![]() * F = Front

* F = Front

This function is useful for users who commonly switch between normal cutting and perforated cutting. You can use this function to prevent products from being wasted due to the tool being installed in the incorrect position.

When one of the messages shown above is displayed, install the cutting tool in the correct position, and then press [PAUSE]. The pausing of machine operations is released, and the tool position is detected again. Cutting starts if the tool installation position is correct.

Note that even if you disable [BLADE DETECT], when you send data that contains a mix of normal cutting and perforated cutting, the second message shown above will be displayed when normal cutting finishes.

] several times to display the screen shown in the figure.

] several times to display the screen shown in the figure.

].

].

] and [

] and [