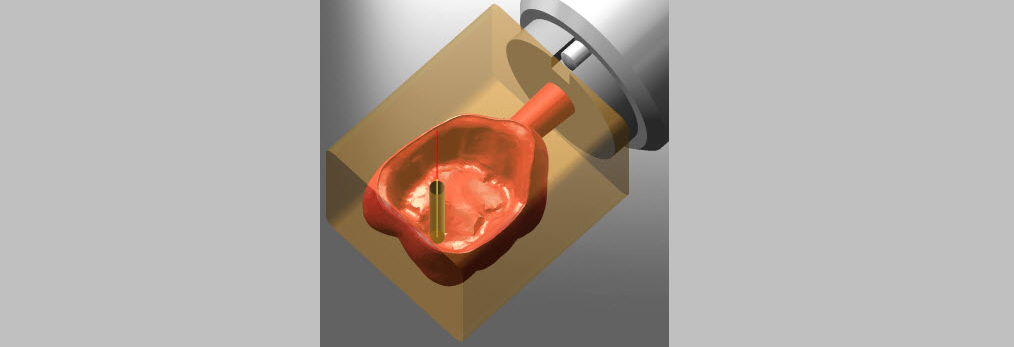

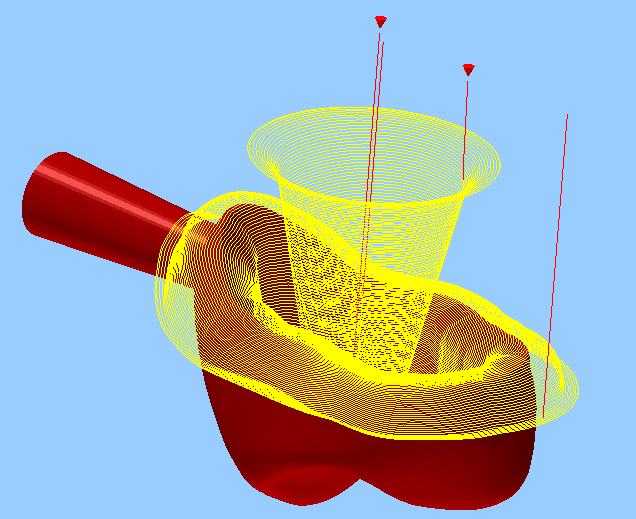

Pre-drilling for grinding the coping and machining with upward tool movement only, no full cut for 5X peeling.

|

Cycles

|

|

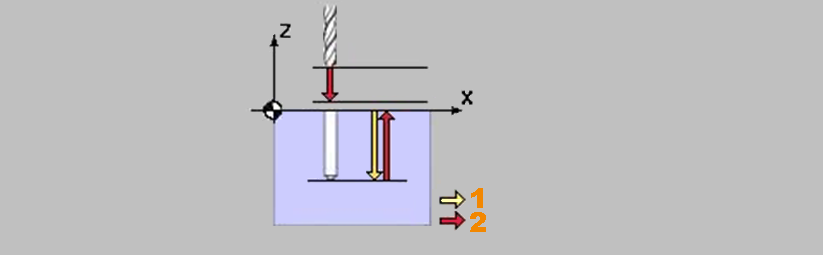

Simple drilling

|

The drill hole is created in a single step, e.g., for center drilling, pre-drilling.

1) Feedrate

2) Rapid traverse

|

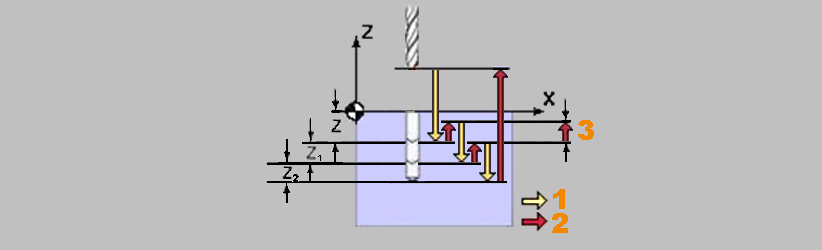

Drilling with chip break

|

The drill hole is created in several steps (Z1, Z2, Z...).

After each drilling stroke, the tool retracts in rapid traverse mode by the retract value (3): shorter chips and better chip removal.

The step (infeed) is reduced by the reduction value after each drilling stroke.

1) Feedrate

2) Rapid traverse

3) Retract value

|

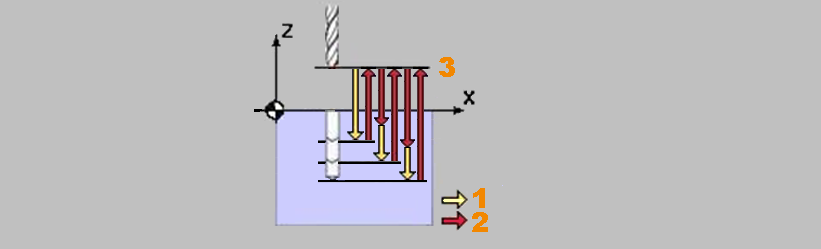

Drilling with pecking

|

The drill hole is created in several steps (Z1, Z2, Z...).

After each drilling stroke, the tool retracts in rapid traverse mode to the clearance distance (3): The drill hole is cleared.

The step (infeed) is reduced by the reduction value after each drilling stroke.

1) Feedrate

2) Rapid traverse

3) Clearance distance

|

Spiral milling

|

Finishing of the precise final diameter of the hole in a spiral milling process.

The combination of pre-drilling with a drill and spiral milling of any diameter enables fast, flexible production with just a few tools.

|

|

|

Hole diameter

|

mm

Final diameter of the hole during spiral milling.

|

Cone angle

|

(only for 5X dental finishing)

Angle for opening the hole.

|

Side

|

Side on which processing takes place.

|

Front

Back

Left

Right

Top

Bottom

Inside copings

Occlusal insertion direction

|

|

Position

|

Position of the drill hole. This information is important for the position of subsequent machining.

|

Mid of coping

|

The drill hole is made in the center of the coping.

|

Deepest point in coping

|

The drill hole is made at the lowest point of the coping.

Caution! Synchronization with the pre-drilling job of the infeed point in the center during “Overall finishing cavity side (cap) – 3D equidistant finishing flow.”

Prerequisites:

Pre-drilling job => Side => Bottom

General settings in the job => Outer machining ortho to blank => Yes

|

Top

|

Definition of where drilling is to start.

|

Blank

|

Surface of the blank.

|

Convex envelope

|

Top of the convex envelope.

|

Automatic

|

The program determines the starting point.

|

Offset top

|

mm

Additional offset for the starting point of the drilling.

|

Pecking depth

|

Infeed of the tool in mm, in the first drill stroke.

|

Reduce value

|

mm

Reduction of the infeed after each additional drilling stroke.

|

Stepover

|

mm

Lateral infeed during spiral milling.

|

|

|