Machining of long cavities for the production of occlusal splints.

The splints lie over the existing teeth as protection and must enclose them up to below the maximum tooth thickness to ensure a secure hold. For this reason, the splints have undercuts. The undercuts extend over the entire area of the cavity and exhibit opposite angles on both sides of the cavity as regards the insertion and machining direction.

Depending on the settings in the template, hyperDENT can automatically detect such long splint cavities and divide them into individual segments for machining on 3+2 machines.

|

|

•Automatic division into segments for machining long cavities. •Separate machining of end areas. •Machining of a splint for an entire tooth sector with gaps. |

|

|

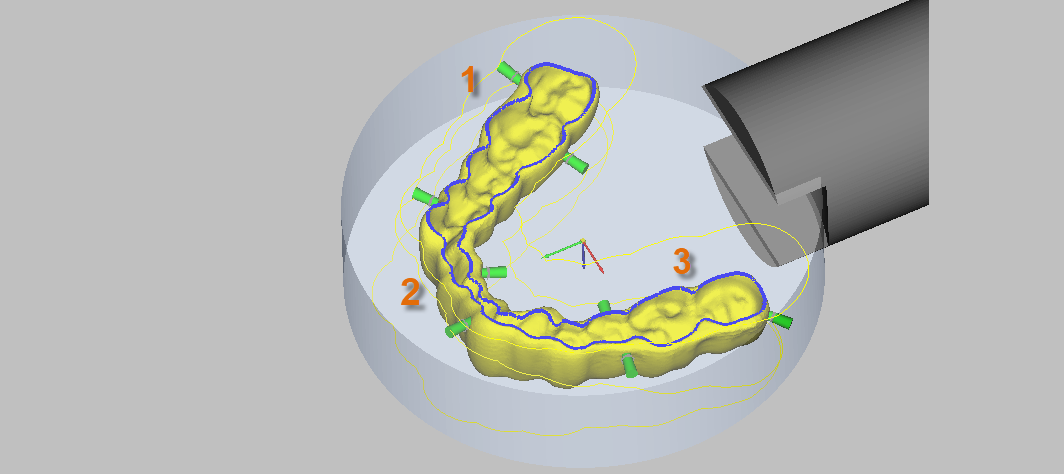

Example splint with 3 segments (1, 2, 3)

Processing takes place, for example, in 6 or more steps:

3 segments with 2 different tilting angles each.

|

Cycles

|

Segmented profile finishing

Segmented profile finishing XY-optimized

Segmented equidistant finishing

|

|

|

Finishing on the inside of long cavities

|

Angular difference of segments

|

Angular deviation of the center line of the cavity, used for the automatic subdivision into part sections (segments). The smaller the value, the more segments are generated.

|

Angle of end segment

|

Angle used to define the size of the end segment.

|

0

|

No end segment.

|

>0

|

An end segment is generated.

|

|

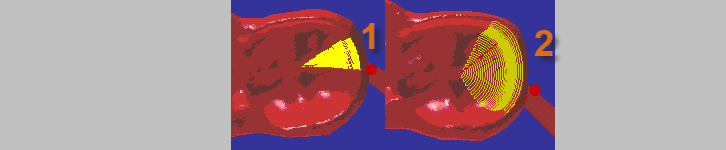

1) End segment with an angle of 30°

2) End segment with an angle of 120°

|

Desired tilt angle

|

Tilt angle for machining the segment.

|

|

|

Finishing inside copings

|

Within a splint for an entire tooth sector with gaps, there may be short cavities for individual teeth that can be processed using this job.

|

Calculate if

|

|

Small cavity

|

The calculation is only carried out for small cavities. Required for machining individual teeth within a splint, e.g., if there are gaps between teeth.

|

|

|