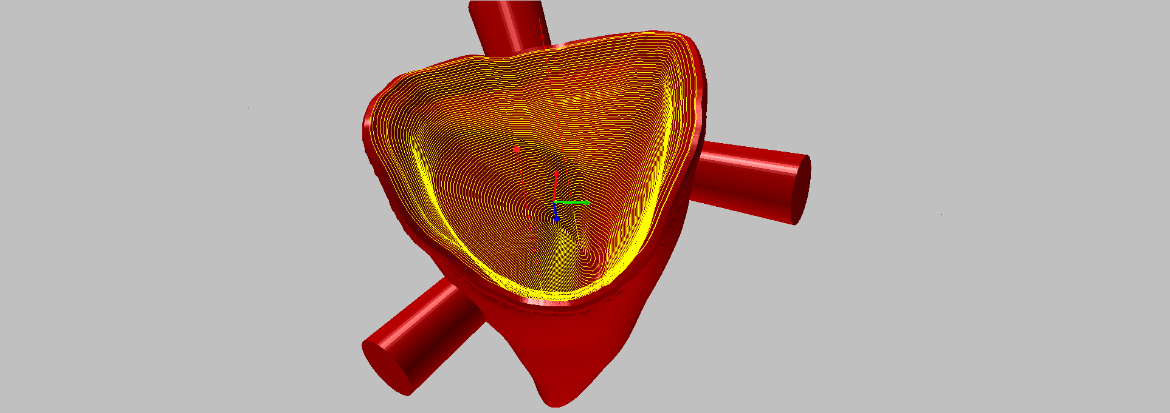

Targeted pre/fine finishing in the area inside of the coping starting from the margin line.

|

Cycles:

|

3D equidistant finishing

3D complete finishing

5X boss finishing

4X Boss finishing

5X peeling

3D Z-Level finishing

|

|

|

Max. angle for red. feedrate:

|

|

Value 0

|

Full feedrate; with a different value, the feedrate is reduced during plunge movements.

|

Offset

|

When set to “0,” the margin line is protected by an automatically generated auxiliary geometry. This means that this sensitive area is skipped during the coping machining process.

|

Value < or > 0

|

No protection. An offset function is called up.

|

Values > 0

|

The offset is generated outside of the margin line.

|

Values < 0

|

The offset is generated inside of the margin line.

|

Trim lenght

|

The tool paths can be trimmed inwards by a defined distance = trim lenght. If an offset has been defined, the calculation of the trim length starts from the offset.

|

|

|

Be careful when machining undercut areas that start directly at the margin line:

If you enter an offset < 0, the machining inside the coping may fail.

|

|

Category

|

... 0 ... 9 ... n

Number for this machining process.

You can use this number to assign this process to a cavity.

The calculation only takes place if an area is assigned the corresponding category number: --> “Identify part features.”

This makes it possible to process different cavities using only one (extensive) template.

This is especially useful for machining telescopes.

|

/

|

You can use the separator to process several categories in a single job. Example: 1/2 (usable for all category types)

|

*

|

All categories are calculated (usable for all category types).

|