Front/Back/Left/Right

|

Enter the side to be machined; corresponds to the viewing direction configured [Front view].

|

Example

|

Machining side

|

|

In terms of the view direction, the tool approaches the part from the back, i.e., it approaches the front of the part.

|

|

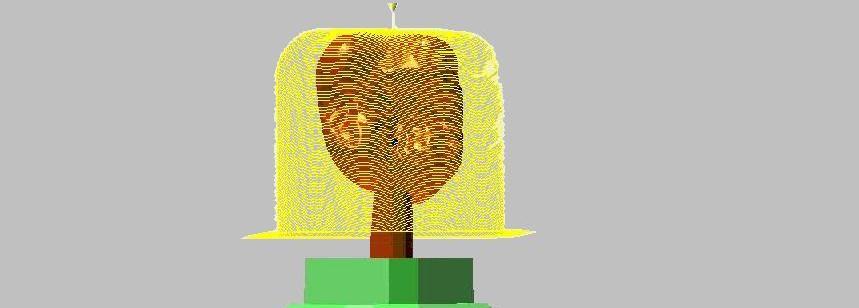

1) Viewing direction: Setting [Front view].

2) Tool: Seen from the viewing direction, the machining area is at the “back” of the blank.

|

Machining depth

|

Parameters for the machining depth applied to the blank.

|

Max. of bounding box

|

Machining area based on “back” view of the blank (bounding box).

Machining from the beginning of the blank to the beginning of the part.

|

Example:

|

Max. of bounding box (with additional offset)

|

Min. of bounding box

|

Machining area based on “from back to front” view of the blank (bounding box). Machining from the beginning of the blank to the end of the part.

|

Example:

|

Min. of bounding box

|

Center of bounding box

|

Machining area based on “from back to center” view of the blank (bounding box).

Machining from the beginning of the blank to the center of the part.

|

Area

|

Define the work area.

|

Outer areas

|

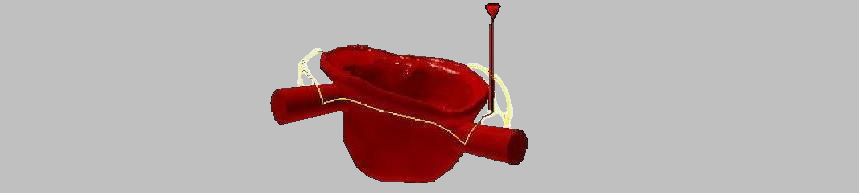

Viewed from the Z-direction, the part is machined up to the equator.

|

All areas

|

The whole part within the confines of the bounding box is machined.

|

Depth offset

|

Additional value for the machining depth. A larger value results in deeper machining.

|

Protected area within the abutment base

|

Enable/disable protection of the abutment base.

|

Use/transform fixture boundary

|

|

Yes

|

When machining a side of the blank,

use milling boundaries for holders.

|

No

|

When machining the front side (from the perspective of the fixture).

|

Close caps

|

You must select “Yes” if the “Special function coping-specific alignment” option has been configured for the part.

You also need to select “Yes” for the following finishing cycles of the cavity.

|

|

|

Min. depth

|

|

None

|

The roughing depth depends on the course of the equator.

|

Mid of boundmesh

|

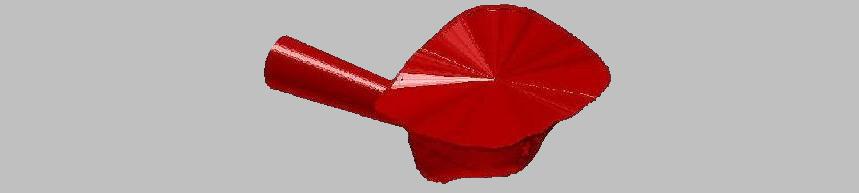

Setting the “Boundary angle” and “Startheight of opening angle” parameters causes a cone to be produced on both sides for the machining. The cutting point of both cones defines the “Mid of boundmesh” area.

|

Top of part

|

Machining up to the highest point of the part.

|

Mid of part

|

Machining up to the center of the part.

|

Bottom of part

|

Machining to the lowest point of the part.

|

Top of blank

|

Machining up to the upper edge of the blank.

|

Mid of blank

|

Machining up to the center of the blank.

|

Bottom of blank

|

Machining up to the lower edge of the blank.

|

Finish pass

|

The smoothen roughing depth that the roughing cycle has created to protect the following tools during subsequent machining: Yes/No

|

Planar mode

|

Tool movement for roughing.

|

Rapid in

|

The tool’s full cut is suppressed; suitable for grinding strategies.

|

Optimized in

|

Standard setting for roughing; unsuitable for grinding strategies.

|

Inside out

|

Roughing from the inside to the outside.

|

Caution! Tool full cut is possible. Therefore, the [Optimized in] setting is not suited for grinding strategies.

|