The main direction indicates the machining direction of the tool in relation to the part. Make sure that there are no undercuts.

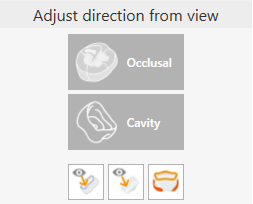

Set the main direction (= machining direction) for the part:

|

|

|

Occlusal

|

Define side as occlusal side. By pressing the button, the current view of the part is defined as the occlusal side in the editing window.

|

|

Cavity

|

Define side as cavity side. By pressing the button, the current view of the part is defined as the cavity side in the editing window.

|

|

Rotate view to cavity side

|

Click this to rotate the view to the most recently defined cavity side.

|

|

Rotate view to occlusal side

|

Click this to rotate the view to the most recently defined occlusal side.

|

|

Undercut view

|

The undercuts are highlighted in red on the part. The undercut areas can be minimized through fine adjustment of the main direction. Machining within margin lines is defined separately and does not have to correspond to the main direction.

|

|

Fine adjustment of the milling direction

|

|

Arrow keys

|

Rotate the part in the direction the arrow is pointing by the set step value (degrees).

|

Setting angle steps

|

|

|

Angle step size in degrees

|

|

|

|

|

|

|

|

|

|

![]() Main direction

Main direction