|

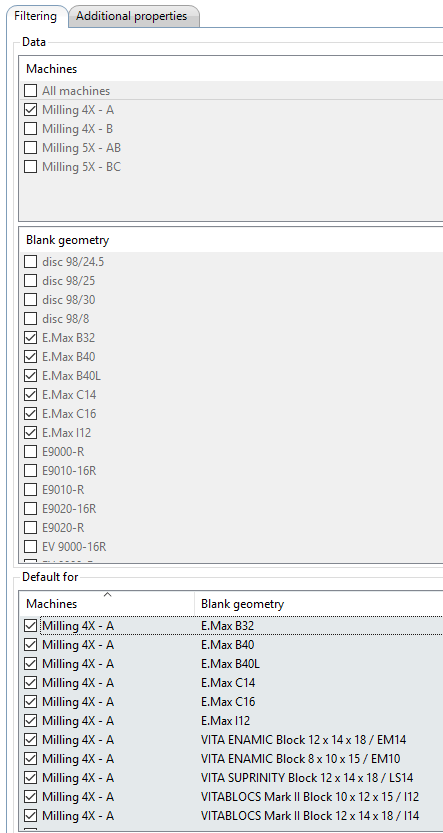

In order to increase automation, it is necessary to assign machine and clampable blank geometries to the fixtures as clearly as possible.

To define these, open the Settings -> Machining... -> Fixtures menu item.

|

Assign the machine to the selected fixture.

Only available with the “Multi machine” option.

|

Assign the blank geometries to the selected fixture.

|

Presetting for the machine, fixtures, and blank geometry. If the settings are unambiguous, loading a blank automatically loads the machine with the appropriate fixture.

|

|

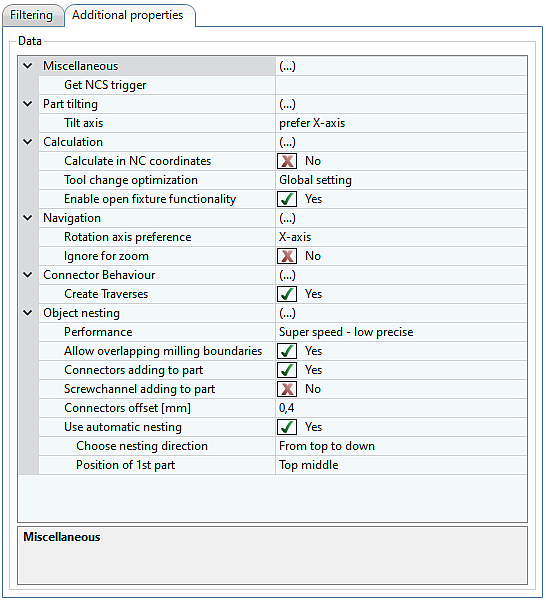

Use the additional settings to define further fixture-dependent parameters.

|

Part tilting:

Set the tilting axis for automatic tilting. (See also “Automatic tilting”)

|

Calculation:

Calculate in NC coordinates (necessary for Roland DWX-52DC and Calculation Merge).

Tool change optimization – specific setting options for tool change-optimized calculation.

Enable open fixture functionality - With open fixtures (C-clamp), the option must be activated to use the corresponding functionality.

|

Navigation:

Rotation of the view over the selected axis.

Ignore for zoom: If this option is activated, the Zoom All function  will fit the stock independently of the holder in the graphics window. will fit the stock independently of the holder in the graphics window.

|

Connector behavior:

“Yes” if connectors are calculated for several parts with overlapping milling area boundaries, traverses are placed between the parts.

|

Object nesting:

Option for setting automatic part nesting. Automatic nesting if you set “Use automatic nesting” to “Yes.” You can set the nesting direction.

|

|