This job was developed for efficiently processing the corners of implant connections. Sharp-edged corners cannot be produced with a round tool. However, various strategies are available for combining components.

|

Strategies

|

|

Simple drilling

Drilling with chip break

Drilling with pecking

3D contour milling

|

|

Offset to screw channel center

|

Value > 0 --> Drill position shifts towards screw channel center, starting from the corner position.

The offset value depends on the tool radius.

|

Top

|

|

Automatic

|

The cycle knows where to start due to blank tracking.

|

Maximum inside abutment area

|

Highest point of the abutment base geometry is used.

|

Offset top

|

Value > 0 --> Machining starts at a higher position.

|

Machining depth

|

|

Value used for “Top” parameter

|

Depth results from “Top” + “Offset top”

|

Corner position

|

Depth results from the position of the defined corner

|

Length

|

Length of the cutting path starting from the corner position incl. “Offset to screw channel center” in the direction of the screw channel center

|

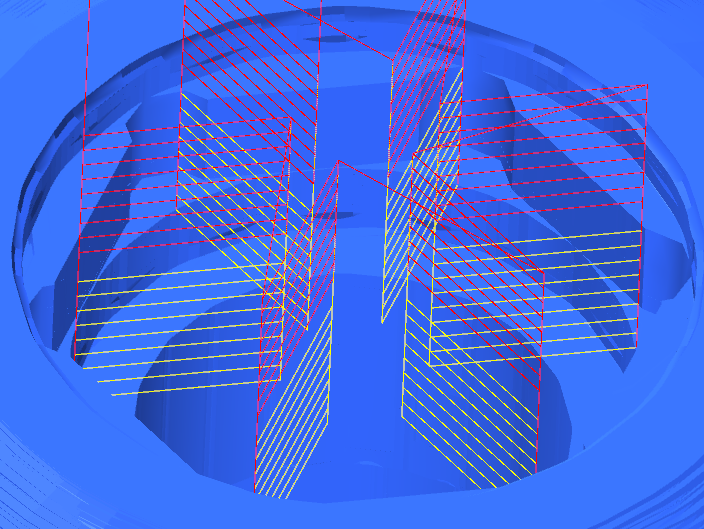

Example: 3D contour milling

|