Diameter referenced tool

|

Enter the diameter of the tool from the job that has just been completed.

Since the cycle has no blank tracking, the theoretical rest machining only refers to the referenced tool.

|

Boundary offset

|

Value to protect the margin line for zirconium oxide. This prevents the cycle from identifying and machining rest material at the margin line.

|

Values < 0

|

The offset is generated inside of the margin line.

Keep the value as small as possible, up to approx. -0.5.

If possible, use the offset in combination with an activated “clip boundary.”

|

Z-level optimization

|

|

Yes

|

Machining in narrow areas (pockets) is performed layer by layer using deep plunging.

Suitable for clearing out deep pockets that are deeper than the current tool diameter.

|

No

|

Z-level optimization is disabled.

|

Clip boundary

|

|

Yes

|

Also sets the boundary of the margin line as the stop area so as to better protect the margin line from unintentional machining.

Where possible, set to “Yes” if a “Boundary offset” is defined.

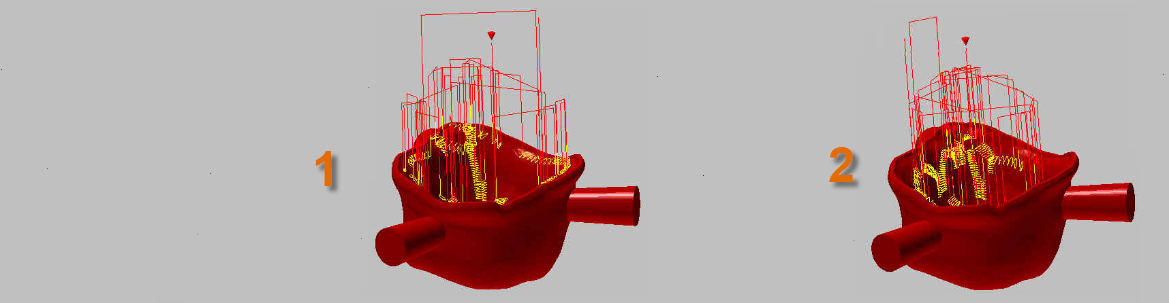

1) Toolpath without set parameter “Clip boundary”

2) Toolpath with set parameter “Clip boundary”

|

Strategy flat areas

|

|

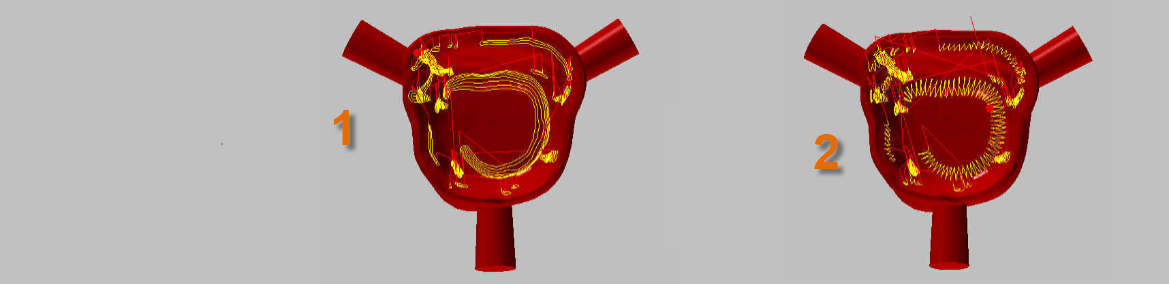

Parallel

|

In flat areas (1), the toolpaths run parallel to the surface of the workpiece.

|

Normal

|

In flat areas (2), the toolpaths run helical to the surface of the workpiece.

As regards machining safety, “Normal” is suitable for material that is difficult to cut.

|

|

|

All areas

|

|

Yes

|

Machine all areas.

|

No

|

Reduce milling boundary so that not all areas are machined, e.g., connectors: shorter machining time.

|

Cutting depth flat areas

|

Maximum processing depth in flat areas.

This value can be chosen liberally if the “Normal” option is set in the “Strategy flat areas” parameter so that the existing rest material is also removed.

|

Slope dependent machining

|

Inclination-dependent machining for “3D and 5X automatic rest material” in order to process the rest material with parallel strategies. The aim is to achieve better toolpaths during grinding.

|

Yes

|

Behavior as before.

|

No

|

Rest material processed using parallel strategy.

|